Until a few years ago thinking about evaporative plastic refrigeration equipment was impossible. The materials used for this purpose were reduced to those based on cellulose, such as cardboard, or those composed of wood chips. Fortunately, technological advances and chemical advances have led to an unparalleled evolution in the creation of new materials and application to the most diverse purposes. Thanks to this, little by little, it is getting that the performance of these equipment overcomes the old disadvantages of the aforementioned materials. For this reason today we want to explain how the field of evaporative cooling improves the use of plastic.

To begin with, if high density polyethylene is used as a plastic, we are talking about a high strength material with ideal qualities for its use. In this way the first advantage it brings is durability. When cardboard is used, even other types of plastic, the wear of these is very fast, and every so often they must be changed to continue fulfilling their function. On the contrary this plastic, the high density polyethylene, the only one used by Control y Ventilacion, S.L. in its evaporative plastic refrigeration equipment, it significantly delays aging.

The other great advantage of this material is its cleaning. Since it is not a porous material, it is impossible to fix bacteria, fungi and other types of microorganisms in it. In addition, this type of surfaces can easily withstand cleaning processes, even with pressurized water, that is, they can be cleaned quickly and easily simply with water, bringing their durability to the long term, measuring their durability in years and even decades.

In Control y Ventilacion we have spent a lot of time researching how to improve the fillings of cooling towers and evaporative cooling equipment every day, so we are pioneers in the use of plastic, High Density Polyethylene, for this purpose.

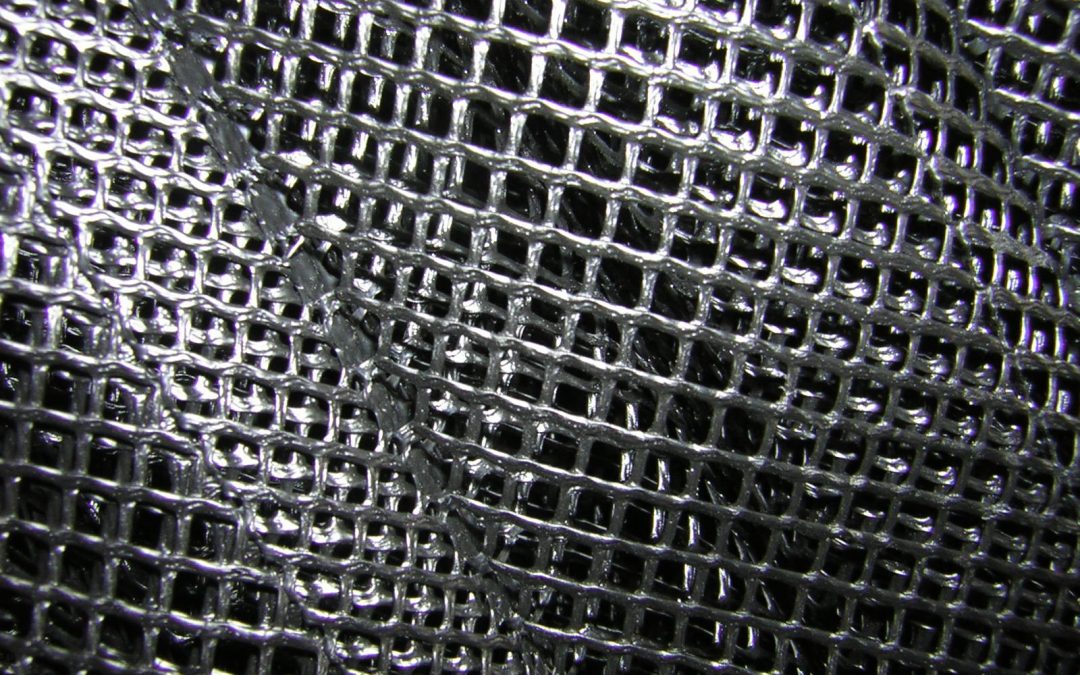

Control y Ventilacion, S.L. is a company of international renown within the industrial and livestock sector, for being a manufacturer of products within the evaporative cooling sector, such as the HUMIBAT, evaporative plastic cooler; or its NUCLEOS towers, Cooling Towers. In both products, the substrate in which the evaporative process is produced is a plastic honeycomb, a honeycomb resistant both to physical and chemical attacks, and at the same time flexible, a honeycomb with a mesh structure, made of polyethylene High Density, and marketed under the names of PANAL C & V or in the case of being a drop separator, SEPARADOR C & V .

For more information you can see the following links:

www.controlyventilacion.com/refrigeracion-evaporativa/

www.controlyventilacion.com/relleno-y-separador/

www.controlyventilacion.com/torres-de-refrigeracion/

Recent Comments